Traditional vs. Modern Scaffold Design: Why 2D is Holding You Back

In an industry where time, accuracy, and collaboration define success, scaffolding companies still relying on traditional 2D design methods are at a significant disadvantage.

The days of static PDFs and guesswork are over—modern scaffolding design workflows powered by intelligent 3D platforms like ScaffPlan and Trimble Connect are transforming how projects are planned, designed, and executed from day one.

In this article, we explore the key differences between traditional and modern scaffolding project design, and how embracing 3D platforms leads to improved accuracy, better collaboration, and substantial cost savings.

Traditional Project Setup: Why 2D Is No Longer Enough

For decades, 2D drawings have been the standard for scaffolding project setup and planning. While familiar, this method has significant limitations that impact performance—especially on complex projects.

The Core Problems of 2D Drafting

-

Lack of Depth and Perspective:

2D drawings are flat, making it difficult to visualise height, depth, and spatial relationships. Without spatial context, critical elements—like tube positions, connections, or clearance zones—can be misinterpreted, increasing the risk of errors during erection. These inaccuracies may only become apparent on-site, leading to costly rework, delays, and safety concerns. -

Manual Updates = More Errors:

Since each drawing view is isolated, any change to the scaffold layout requires repetitive redrawing and coordination between views—an inefficient and error-prone process. This fragmented approach undermines accuracy, slows down revisions, and makes it difficult to maintain a single source of truth throughout the project lifecycle. -

Inherent Lack of Data Integration:

With no embedded data in scaffold components, teams face data loss and must rely on time-consuming manual annotations to communicate design intent. This disconnect severely limits the ability to extract accurate quantities or generate quick estimates, making 2D an inefficient choice for modern project demands. -

Insufficient Automation:

Simulating scaffold layouts in 2D is a tedious, time-consuming process, making it difficult to simulate and compare design scenarios efficiently. The manual nature of 2D drafting slows down decision-making and increases the risk of suboptimal solutions. As project complexity grows, the inability to automate scenario testing or optimise layouts in real-time highlights the fundamental limitations. -

Collaboration Issues:

Traditional methods lack integrated collaboration tools, making it difficult for teams and stakeholders to stay aligned throughout the project lifecycle. Communication is often fragmented, relying on static files and manual updates that hinder real-time coordination. This disjointed workflow contributes to misinterpretation, rework, and costly delays—highlighting the need for connected, data-driven platforms that support modern project demands.

The Impact?

- Design misalignment leading to costly rework

- Time-consuming estimation, planning, revision and approval processes

- Escalated project costs

- Elevated risk during erection phases

The Modern Scaffold Design Workflow: 3D Modelling and Connected Workflows for Maximum Accuracy

.jpg?width=575&height=302&name=ScaffPlan%20blog%20images%20(1).jpg) Today’s scaffolding projects begin with precise 3D models that provide spatial clarity and reduce design ambiguity from the outset. Platforms like ScaffPlan and Trimble Connect enable real-time collaboration, allowing teams to coordinate seamlessly across disciplines and project phases from day one.

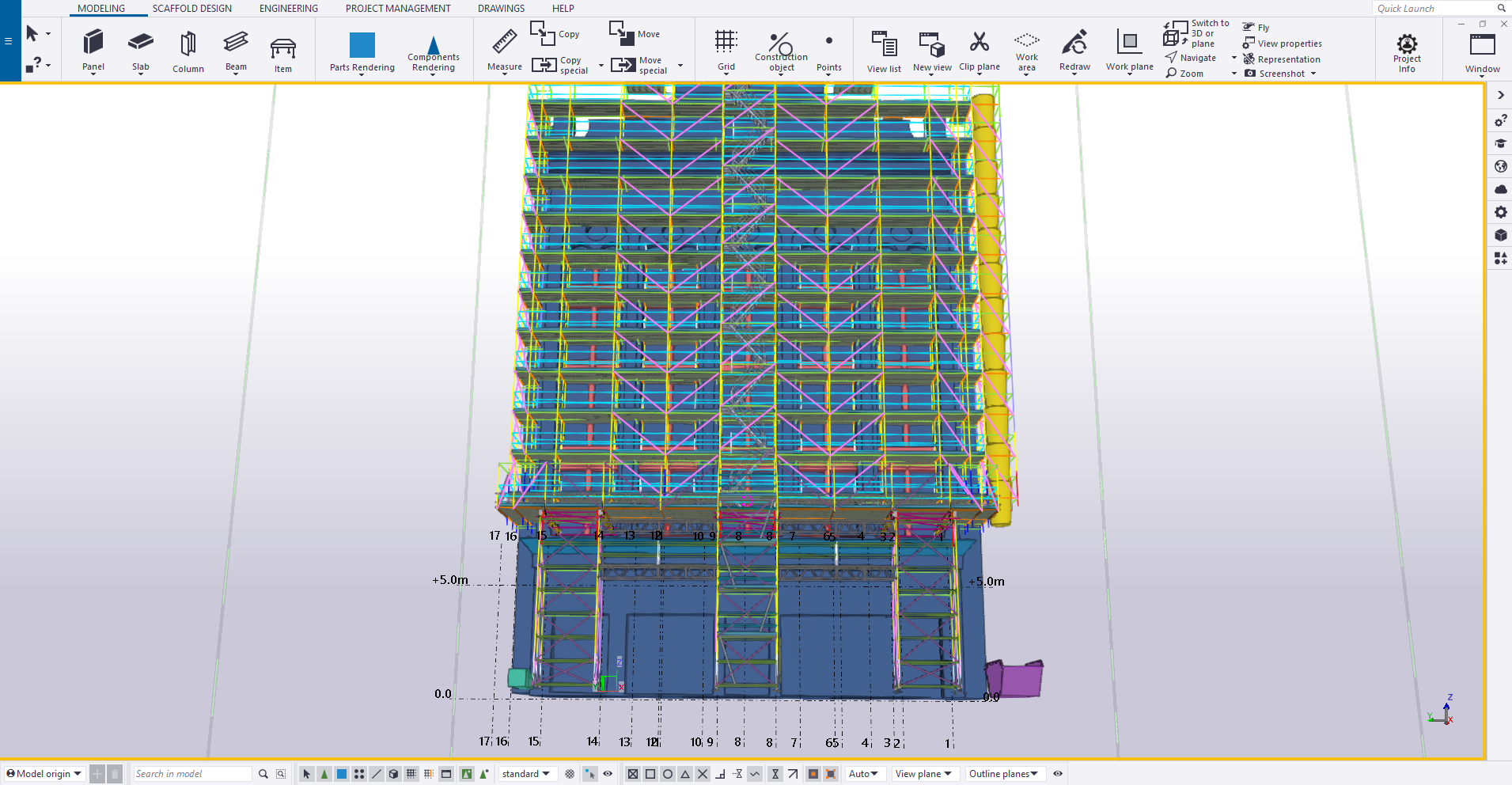

Today’s scaffolding projects begin with precise 3D models that provide spatial clarity and reduce design ambiguity from the outset. Platforms like ScaffPlan and Trimble Connect enable real-time collaboration, allowing teams to coordinate seamlessly across disciplines and project phases from day one.

This connected, 3D model-based, data-driven approach transforms how scaffolding is scoped, designed, and executed—improving accuracy, efficiency, and safety at every stage by solving issues before they happen onsite.

Importing Widely-Used 3D Models from Day One

From day one of a project with ScaffPlan, teams can import widely-used 3D models such as:

- SketchUp

- IFC (Industry Foundation Classes)

- Point clouds

This capability gives immediate visual clarity into the real-world environment, eliminating manual interpretation and guesswork from the beginning.

Why Does a 3D Model Matter in Scaffolding Design?

ScaffPlan replaces flat 2D visuals with accurate, data-rich 3D models that offer complete spatial awareness. Designers can visualise height, depth, and clearance zones with precision, reducing ambiguity and eliminating misinterpretations.

Real-time 3D visualisation allows teams to identify potential clashes or safety concerns long before materials reach the site—cutting rework, delays, and risk.

What is 3D Model-Based Drawing Production?

In ScaffPlan, the dynamic scaffold model is connected to all drawing views. When changes are made in the 3D model, they automatically propagate throughout the whole set of drawings—from dimensions to component annotations—eliminating the need to manually redraw and annotate multiple views.

This centralised, model-based drawing generation approach ensures:- Consistency across all drawings

- Faster revisions

- A reliable single source of truth—the 3D model—that keeps everyone aligned

.jpg?width=575&height=302&name=ScaffPlan%20blog%20images%20(2).jpg)

What Is a Data-Rich Model and How Does It Enhance Scaffolding Projects?

Every component in ScaffPlan carries real data, including:

- Dimensions

- Material types

- Weight

- Cost

- Custom data fields you can write into any component

This data-rich model enables:

- Instant quantity take-offs

- Automatic gear lists

- Accurate estimating with minimal manual input

With seamless export and integration, project teams can move from design to execution with clarity and confidence. It also allows changes in the 3D model, such as adjusting a bay or component, to automatically update dimensions and annotations on drawings without manual input.

Why Is Automation Critical in Scaffold Design Tools?

ScaffPlan enables fast scenario testing and layout optimisation using built-in automation tools. Teams can quickly:

- Simulate design variations

- Evaluate different access strategies

- Refine layouts in real time

.gif?width=450&height=300&name=2025%20450%20%20compressed%20WEBSITE%20-%20ScaffPlan%20GIFS_FEATURE%20%2B%20Shadow%20Background%20(450%20x%20300%20px).gif)

Sharing 3D design mock-ups with project managers and stakeholders from the beginning of a project accelerates decision-making and empowers teams to deliver more efficient and cost-effective scaffolds.

How Does Trimble Connect Enhance Collaboration in Scaffolding Projects?

Trimble Connect enhances the modelling environment by providing a shared cloud-based platform for all project stakeholders. Features include:

- Real-time access to 3D models, comments, TODOs, 2D references, and updates

- Ensuring all parties always work with the latest information—a single point of truth

This level of transparency eliminates silos, reduces communication breakdowns, and promotes faster, more informed project coordination.

The Results Speak for Themselves

✅ Clear Project Scope – Get alignment early and avoid rework

✅ Maximum Accuracy – From initial layout to scaffold erection

✅ Cost-Effective Planning – Eliminate inefficiencies before they happen

✅ Seamless Collaboration – All stakeholders on the same page

Ready to Leave 2D Behind?

If your team is still relying on outdated project planning methods, it’s time to upgrade your workflow. By adopting a 3D scaffolding design solution like ScaffPlan integrated with Trimble Connect, you can boost efficiency, accuracy, and collaboration across every stage of your scaffolding project.